Kasipalayam, Erode, Tamil Nadu

- GST NO. : 33BBVPP3023P1Z3

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Usage/application | Industrial |

| Automation Grade | Fully Automatic |

| Click to view more | |

Preferred Buyer From

| Location | India ( Andhra Pradesh, Karnataka, Kerala, Tamil Nadu, Telangana only) & All other countries |

Product Details

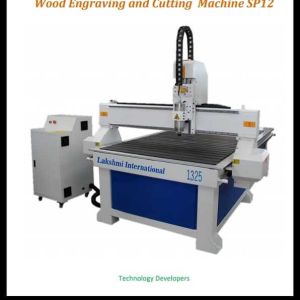

Are you looking for 2D CNC Wood Lathe Machine Manufacturer in India? You are in the right place. Our company Laxmi International is the right choice.

The versatility of the CNC lathe machine makes it an excellent tool for organizations in a variety of industries, especially automotive, healthcare, electronics and aerospace.

A CNC lathe machine can produce a range of products, from larger items such as automobile frames and aeroplane engines to smaller items, such as surgical instruments, gears and garden tools. It can also produce all kinds of structures, including flat surfaces, threads, and cylindrical components that have inner and outer diameters.

When determining which type of CNC lathe machine you want to purchase or which supplier to partner with, consider the axes of each machine. The axes tend to be an indicator of the machine's capabilities.

The lower the axes, the fewer components it can produce. And the higher the axes, the more complex the capabilities, including milling, tapping, drilling and boring operations. We are the best 2D CNC Wood Lathe Machine Supplier delivering products to your doorstep.

How Does The Machine Work?

A CNC lathe machine comes in a variety of configurations that are specific to the production process and desired components. The machine can be configured horizontally and vertically, and it can contain a slant bed or flatbed, multi-axes, multi-spindles and a b-axis capability to give the machine full support for five-axis index milling.

Although the machine configuration varies, it is made of the following nine main components.

Machine bed: The machine bed serves as the base of the machine on which all other components are mounted.

The main spindle: The main spindle is made up of a spindle assembly and spindle drive system that includes motors, gears and the chuck. The main spindle receives the material and drives it through the process.

Sub-spindle: Sub-spindles, while separate from the main spindle, work in tandem with the main spindle to perform additional cutting operations to improve the efficiency of the production process.

Chuck: Attached to the main spindle, the chuck grips the work piece and rotates the work piece throughout the process.

Guide way: The guide way allows the main spindle and work piece to move vertically and horizontally during the cutting process.

Contact us and order today. We are the best 2D CNC Wood Lathe Machine Supplier in Tamil Nadu.

Looking for "2D CNC Wood Lathe Machine" ?

Explore More Products

Our Blogs